Kev Nug Txog Pricelist

Yog tias koj muaj lus nug txog peb cov khoom lossis daim ntawv teev nqi, thov tawm koj tus email rau peb thiab peb yuav tiv tauj koj tsis pub dhau 24 teev.

Feature

SMC roving yog tsim los muab qib siab ntawm lub zog tensile, uas yog lub peev xwm ntawm cov khoom siv los tiv taus lub zog rub yam tsis tawg. Tsis tas li ntawd, nws qhia txog lub zog flexural zoo, uas yog lub peev xwm los tiv taus kev khoov lossis deformation nyob rau hauv cov khoom siv. Cov khoom siv zog no ua rau SMC roving tsim nyog rau kev tsim cov khoom siv uas xav tau lub zog siab thiab kev tawv.

Daim ntawv thov ntawm SMC roving:

1. Cov Khoom Siv Tsheb: SMC roving yog siv dav hauv kev lag luam tsheb rau kev tsim cov khoom sib dua thiab ruaj khov xws li lub bumpers, lub cev vaj huam sib luag, lub kaus mom, qhov rooj, fenders, thiab cov khoom sab hauv.

2. Cov Khoom Siv Hluav Taws Xob thiab Hluav Taws Xob: SMC roving yog siv los tsim cov khoom siv hluav taws xob thiab hluav taws xob, xws li lub thawv ntsuas, lub thawv sib txuas, thiab cov txee tswj.

3. Kev Tsim Kho thiab Kev Tsim Kho Vaj Tse: SMC roving yog siv rau hauv kev lag luam kev tsim kho rau kev tsim ntau yam khoom siv hauv tsev, suav nrog cov facades, cladding panels, structural supports, thiab utility enclosures.

4. Cov Cheebtsam Aerospace: Hauv kev lag luam aerospace, SMC roving yog siv rau kev tsim cov khoom sib dua thiab muaj zog xws li cov vaj huam sib luag sab hauv, cov khoom ncaj ncees, thiab cov khoom siv rau dav hlau thiab spacecraft.

5. Cov Tsheb Ua Si: SMC roving yog siv rau hauv kev tsim cov tsheb ua si (RVs), nkoj, thiab lwm yam kev siv hauv hiav txwv rau kev tsim cov vaj huam sib luag sab nraud, cov khoom sab hauv, thiab cov qauv txhawb nqa.

6. Cov Khoom Siv Ua Liaj Ua Teb: SMC roving siv rau hauv kev lag luam ua liaj ua teb rau kev tsim cov khoom xws li lub tsheb laij teb hoods, fenders, thiab cov khoom siv enclosures.

| Fiberglass sib dhos roving | ||

| Iav hom | E | |

| Kev Loj hom | Silane | |

| Ib txwm muaj txoj hlua txoj kab uas hla (um) | 14 | |

| Ib txwm muaj kab ncaj qhov ceev (txx) | 2400 | 4800 |

| Piv txwv | ER14-4800-442 | |

| Khoom | Kab ncaj qhov ceev kev hloov pauv | Cov dej noo cov ntsiab lus | Kev Loj cov ntsiab lus | Kev tawv |

| Chav tsev | % | % | % | mm |

| Kev Ntsuas txoj kev | ISO 1889 xyoo | ISO 3344 | ISO 1887 xyoo | ISO 3375 |

| Tus Qauv Ntau yam | ±5 | ≤ 0.10 | 1.05± 0.15 | 150 ± 20 |

| Khoom | chav tsev | Tus Qauv | |

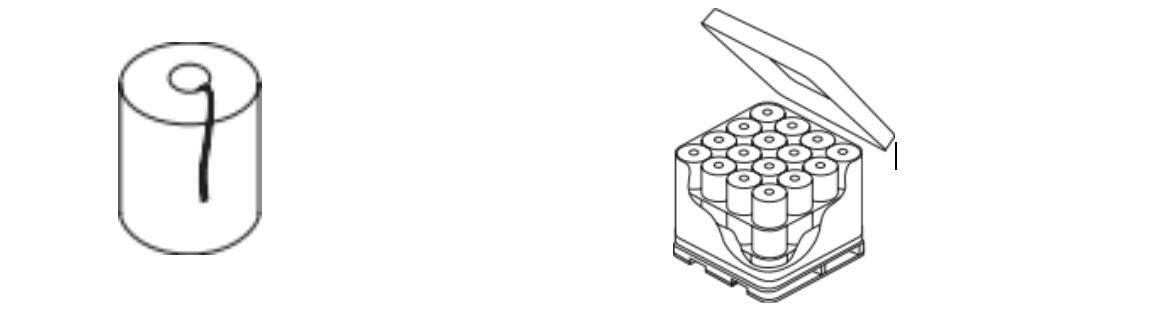

| Ib txwm muaj ntim khoom txoj kev | / | Ntim khoom on cov pallets. | |

| Ib txwm muaj pob khoom qhov siab | mm (hauv) | 260 (10.2) | |

| Pob khoom sab hauv txoj kab uas hla | mm (hauv) | 100 (3.9) | |

| Ib txwm muaj pob khoom sab nraud txoj kab uas hla | mm (hauv) | 280 (11.0) | |

| Ib txwm muaj pob khoom qhov hnyav | kg (lb) | 17.5 (38.6) | |

| Tus lej ntawm cov khaubncaws sab nraud povtseg | (txheej) | 3 | 4 |

| Tus lej of cov pob khoom ib qho txheej | 个(ib daim) | 16 | |

| Tus lej of cov pob khoom ib qho pallet | 个(ib daim) | 48 | 64 |

| Net qhov hnyav ib qho pallet | kg (lb) | 840 (1851.9) | 1120 (2469.2) |

| Pallet ntev | mm (hauv) | 1140 (44.9) | |

| Pallet dav | mm (hauv) | 1140 (44.9) | |

| Pallet qhov siab | mm (hauv) | 940 (37.0) | 1200 (47.2) |

Yog tias koj muaj lus nug txog peb cov khoom lossis daim ntawv teev nqi, thov tawm koj tus email rau peb thiab peb yuav tiv tauj koj tsis pub dhau 24 teev.