Cov Tshuaj Pleev Xim Rau Cov pwm, kuj hu uaTso Tawm Cov Tshuaj Ciabor Cov Tshuaj Pleev Xim Rau Kev Tshem Tawm, yog ib qho tshuaj tshwj xeeb uas tsim los pab kom yooj yim tso tawm cov khoom molded lossis casting los ntawm lawv cov pwm lossis cov qauv.

Cov Khoom Siv: Cov tshuaj pleev xim rau cov roj pleev xim tuaj yeem sib txawv, tab sis feem ntau lawv muaj cov roj pleev xim ntuj, cov roj pleev xim tsim, cov roj av distillates, thiab cov khoom ntxiv. Cov khoom ntxiv no yuav muaj cov neeg sawv cev los txhim kho cov yam ntxwv ntawm kev tso tawm, txhim kho qhov tiav ntawm qhov chaw, tiv taus cua sov, lossis ua kom ruaj khov.

Hom Tshuaj Tso Tawm

Ua los ntawm Carnauba: Carnauba wax, uas yog los ntawm nplooj ntawm tsob ntoo xibtes Brazilian Copernicia prunifera, paub txog nws qhov tawv thiab qhov kub yaj. Carnauba-based release waxes muaj cov yam ntxwv zoo heev rau kev tso tawm thiab feem ntau siv rau hauv cov ntawv thov uas muaj qhov kub siab.

PVA (Polyvinyl Cawv): Cov roj nplaum uas muaj PVA muaj polyvinyl cawv, uas ua rau cov pwm thiab cov khoom siv casting yaj tau hauv dej. Tom qab siv, txheej PVA qhuav ua ib zaj duab xis nyias, uas yooj yim ntxuav nrog dej tom qab rhuav pwm.

Cov roj hmab ua los ntawm cov khoom siv hluavtaws: Cov roj hmab ua los ntawm cov khoom siv hluavtaws thiab cov khoom ntxiv rau hauv cov roj hmab no muaj kev ua haujlwm zoo sib xws thoob plaws ntau yam kub thiab cov ntaub ntawv pwm.

Peb liTso Tawm Cov Tshuaj Ciab

Cov Txheej Txheem Thov:

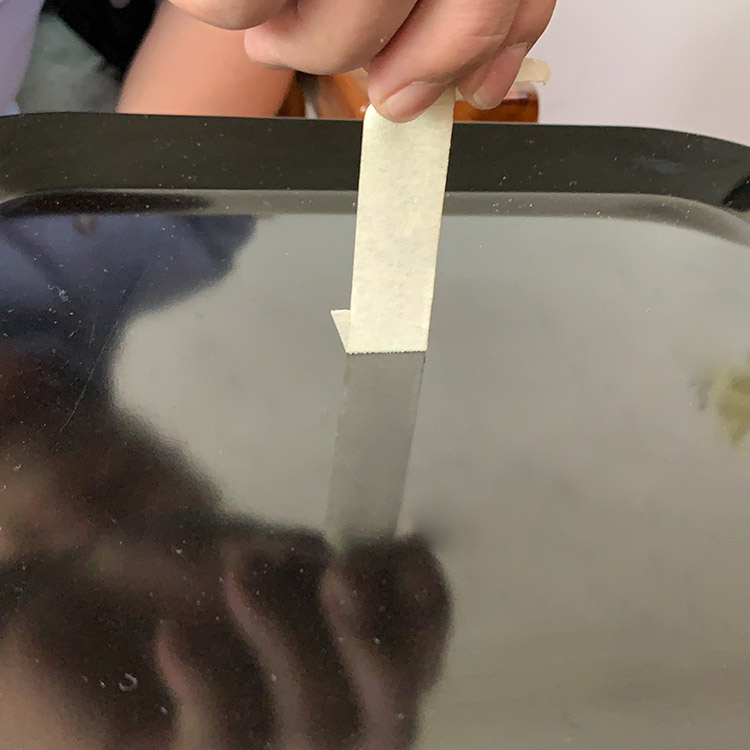

Tso Tawm Cov Tshuaj Ciabtuaj yeem siv tau ntau txoj kev, suav nrog kev tsuag, txhuam, so, lossis dipping, nyob ntawm qhov xav tau tshwj xeeb ntawm cov txheej txheem molding thiab hom pwm.

Feem ntau siv tshuaj tsuag rau cov pwm loj lossis thaum xav tau ib txheej sib npaug. Kev txhuam lossis so tej zaum yuav zoo dua rau cov pwm me dua lossis cov pwm nyuaj dua.

Cov Lus Qhia Txog Khoom

Cov txiaj ntsig ntawm kev tso tawm quav ciab

Kev Tso Tawm Yooj Yim:Qhov txiaj ntsig tseem ceeb ntawmTso Tawm Cov Tshuaj Ciabyog nws lub peev xwm los tiv thaiv kev sib txuas ntawm cov pwm thiab cov khoom siv casting, ua rau yooj yim rhuav cov khoom yam tsis muaj kev puas tsuaj.

Kev Tiv Thaiv Nto:Cov quav ciab tso tawm ua ib daim thaiv kev tiv thaiv rau ntawm qhov chaw pwm, txo qhov hnav thiab tsim kua muag thiab ua kom lub pwm siv tau ntev dua.

Kev Kho Kom Zoo Dua Qhov Chaw: Tso Tawm Cov Tshuaj Ciabtuaj yeem txhim kho qhov tiav ntawm cov khoom pwm lossis cov khoom pov tseg los ntawm kev sau cov qhov tsis zoo me me hauv qhov pwm thiab txo cov qhov tsis zoo ntawm qhov chaw tiav.

Kev npaj qhov chaw kom zoo yog qhov tseem ceeb ua ntej siv cov quav ciab kom ntseeg tau tias muaj kev nplaum zoo thiab kev npog zoo.

Yuav tsum xav txog qhov sib xws nrog cov khoom siv molding thiab cov khoom siv pwm thaum xaiv cov tshuaj tso tawm.

Yuav tsum tau xav txog tej yam uas yuav tsum tau xav txog ib puag ncig thiab kev nyab xeeb, tshwj xeeb tshaj yog hais txog cov tshuaj uas siv los ua cov kuab tshuaj.Tso Tawm Cov Tshuaj Ciab.

Zuag qhia tag nrho,Tso Tawm Cov Tshuaj Ciabua lub luag haujlwm tseem ceeb hauv kev pab txhawb kev ua haujlwm zoo thiab zoo molding thiab casting txheej txheem thoob plaws ntau yam kev lag luam thiab kev siv.

Yuav Siv Li CasTso Tawm Cov Tshuaj Ciab

Cov Nyhuv NtawmTso Tawm Cov Tshuaj Ciab

SivTso Tawm Cov Tshuaj Ciabua tau zoo suav nrog ob peb kauj ruam tseem ceeb kom ntseeg tau tias siv tau zoo thiab tau txiaj ntsig zoo tshaj plaws. Nov yog cov lus qhia ntxaws ntxaws txog kev siv cov quav ciab tso tawm:

Cov Khoom Siv Xav Tau:

Siv ib daim ntaub huv, mos los yog txhuam applicator, thov ib txheej nyias nyias, sib npaug ntawm cov quav ciab rau tag nrho qhov chaw ntawm lub pwm.

Siv cov tshuaj pleev rau hauv tej qhov me me lossis tej qhov tawg ntawm pwm kom npog tau tag nrho.

Tsis txhob siv cov quav ciab ntau dhau, vim tias cov khoom ntau dhau yuav cuam tshuam rau qhov zoo ntawm cov khoom tiav.

Cia Lub Sijhawm Qhuav:

Cia cov tshuaj pleev kom qhuav tag raws li cov lus qhia ntawm tus neeg tsim khoom. Feem ntau qhov no yuav siv sijhawm ob peb feeb txog ib teev, nyob ntawm hom tshuaj pleev thiab tej yam ib puag ncig.

Tej cov tshuaj pleev xim yuav xav tau ntau txheej kom tau txiaj ntsig zoo tshaj plaws. Yog tias ua li ntawd, rov ua dua cov txheej txheem thov, cia txhua txheej kom qhuav ua ntej siv txheej tom ntej.

Ua kom lub nto du (xaiv tau):

Tom qab cov quav ciab qhuav lawm, koj xaiv tau siv daim ntaub huv thiab qhuav los yog daim ntaub so kom maj mam txhuam cov quav ciab kom cov quav ciab du thiab du. Kauj ruam no yog xaiv tau tab sis yuav pab kom cov quav ciab tsis lo rau.

Kev txhaj tshuaj los yog casting:

Thaum cov quav ciab qhuav lawm thiab txhua yam kev txhuam buffing tiav lawm, txuas ntxiv mus nrog cov txheej txheem molding lossis casting li niaj zaus.

Ncuav los yog siv cov khoom siv pwm rau hauv pwm uas tau npaj tseg, xyuas kom meej tias nws puv tag nrho cov qhov thiab cov ntsiab lus sib npaug.

Kev Kho Los Yog Kev Kho Kom Ruaj:

Cia cov khoom pwm kom khov lossis khov tag raws li cov lus qhia ntawm tus neeg tsim khoom. Qhov no yuav suav nrog kev tos ib lub sijhawm tshwj xeeb lossis tso cov pwm rau qee qhov kub thiab txias.

Kev Tshem Tawm Khoom:

Tom qab cov khoom siv pwm tau kho tag lossis khov lawm, ua tib zoo tshem cov khoom tiav tawm ntawm pwm.

Cov tshuaj pleev yuav tsum ua kom yooj yim tshem tawm, cia cov khoom sib cais ntawm cov pwm yam tsis lo.

Kev Ntxuav:

Yog tias tsim nyog, ntxuav cov quav ciab uas tseem tshuav ntawm qhov pwm thiab cov khoom tiav lawm.

Xyuas kom tseeb tias cov pwm tau ntxuav kom huv si thiab rov siv cov tshuaj pleev ua ntej siv tom ntej, yog tias siv tau.

Peb liCov Tshuaj Pleev Xim Rau Cov pwmtau txais cov lus tawm tswv yim zoo hauv kev xyaum. Tiv tauj peb kom paub ntxiv txog peb cov khoom.

Tiv Tauj Peb:

Xov tooj: +8615823184699

Email: marketing@frp-cqdj.com

Lub Vas Sab Hauv Internet: www.frp-cqdj.com

Lub sijhawm tshaj tawm: Plaub Hlis-22-2024