Kev tso tes yog ib qho txheej txheem FRP molding yooj yim, pheej yig thiab zoo uas tsis tas yuav siv ntau yam khoom siv thiab peev txheej thiab tuaj yeem ua tiav qhov rov qab los ntawm peev hauv lub sijhawm luv luv.

1. Txau thiab pleev xim rau cov tsho tiv no gel

Yuav kom txhim kho thiab ua kom zoo nkauj ntawm cov khoom FRP nto, ua kom tus nqi ntawm cov khoom nce ntxiv, thiab xyuas kom meej tias txheej sab hauv ntawm FRP tsis raug lwj thiab ntev lub neej kev pabcuam ntawm cov khoom, qhov chaw ua haujlwm ntawm cov khoom feem ntau yog ua rau hauv ib txheej nrog cov xim pleev xim (xim pleev xim), cov ntsiab lus resin siab ntawm cov txheej nplaum, nws tuaj yeem yog cov resin ntshiab, tab sis kuj txhim kho nrog qhov chaw xav. Cov txheej no hu ua txheej txheej gel (tseem hu ua txheej saum npoo lossis txheej kho kom zoo nkauj). Qhov zoo ntawm cov txheej txheej gel cuam tshuam ncaj qha rau qhov zoo sab nraud ntawm cov khoom nrog rau kev tiv thaiv huab cua, kev tiv thaiv dej thiab kev tiv thaiv kev yaig ntawm cov tshuaj lom neeg, thiab lwm yam. Yog li ntawd, cov ntsiab lus hauv qab no yuav tsum tau sau tseg thaum txau lossis pleev xim rau txheej txheej gel.

2. Kev txiav txim siab ntawm txoj kev ua haujlwm

Txoj kev ua cov txheej txheem muaj feem cuam tshuam nrog ntau yam xws li qhov zoo ntawm cov khoom, tus nqi ntawm cov khoom thiab lub voj voog tsim khoom (kev ua haujlwm zoo ntawm cov khoom). Yog li ntawd, ua ntej npaj cov khoom tsim tawm, nws yog ib qho tsim nyog kom nkag siab txog cov xwm txheej kev siv tshuab (ib puag ncig, kub, nruab nrab, thauj khoom ……, thiab lwm yam), cov qauv khoom, qhov ntau ntawm cov khoom tsim tawm thiab cov xwm txheej tsim kho thaum siv cov khoom, thiab tom qab kev tshuaj xyuas thiab kev tshawb fawb, txhawm rau txiav txim siab txog cov txheej txheem molding, feem ntau hais lus, cov hauv qab no yuav tsum tau xav txog.

3. Cov ntsiab lus tseem ceeb ntawm kev tsim cov txheej txheem

(1) Raws li cov kev cai ntawm cov khoom siv los xaiv cov ntaub ntawv tsim nyog (cov ntaub ntawv txhawb nqa, cov ntaub ntawv qauv thiab lwm yam ntaub ntawv pabcuam, thiab lwm yam). Thaum xaiv cov ntaub ntawv raw, cov hauv qab no feem ntau yog xav txog.

①Seb cov khoom puas sib cuag nrog cov kua qaub thiab alkaline media, hom media, concentration, siv kub, lub sijhawm sib cuag, thiab lwm yam.

②Seb puas muaj cov kev cai ua tau zoo xws li kev sib kis lub teeb, nplaim taws retardant, thiab lwm yam.

③Hauv cov nqe lus ntawm cov khoom siv kho tshuab, txawm tias nws yog dynamic lossis static load.

④Nrog lossis tsis muaj kev tiv thaiv kev xau thiab lwm yam kev cai tshwj xeeb.

(2) Txheeb xyuas cov qauv pwm thiab cov khoom siv.

(3) Kev xaiv tus neeg sawv cev tso tawm.

(4) Txheeb xyuas qhov haum ntawm cov tshuaj tua kab thiab qhov system tua kab.

(5) Raws li cov khoom tuab thiab lub zog xav tau, txiav txim siab ntau yam khoom siv txhawb nqa, cov lus qhia tshwj xeeb, tus naj npawb ntawm cov txheej thiab txoj hauv kev los tso cov txheej.

(6) Kev npaj cov txheej txheem molding.

4. Cov iav fiber reinforced yas txheej paste system

Kev tso tes yog ib qho txheej txheem tseem ceeb ntawm kev siv tes ua cov txheej txheem molding, yuav tsum ua haujlwm zoo kom ua tiav qhov ceev, raug, cov ntsiab lus resin sib xws, tsis muaj npuas pom tseeb, tsis muaj impregnation tsis zoo, tsis muaj kev puas tsuaj rau cov fiber thiab cov khoom nto tiaj tus, kom ntseeg tau tias cov khoom zoo. Yog li ntawd, txawm hais tias cov haujlwm nplaum yooj yim, nws tsis yooj yim ua cov khoom zoo, thiab yuav tsum tau coj los ua qhov tseem ceeb.

(1) Kev tswj qhov tuab

Cov iav fiberKev tswj qhov tuab ntawm cov khoom yas uas muaj zog, yog qhov txheej txheem tsim thiab tsim cov txheej txheem yuav ntsib teeb meem kev siv tshuab, thaum peb paub qhov tuab ntawm cov khoom, nws yog qhov tsim nyog los xam kom paub txog cov resin, cov ntsiab lus ntawm cov khoom siv thiab cov khoom siv txhawb nqa uas siv rau hauv cov lus qhia, tus naj npawb ntawm cov txheej. Tom qab ntawd xam nws qhov tuab kwv yees raws li cov qauv hauv qab no.

(2) Kev suav cov tshuaj resin

Cov tshuaj resin dosage ntawm FRP yog ib qho tseem ceeb ntawm cov txheej txheem, uas tuaj yeem suav los ntawm ob txoj hauv kev hauv qab no.

Ib qho xam raws li lub hauv paus ntsiab lus ntawm kev sau qhov sib txawv, cov mis rau kev xam cov nqi ntawm cov resin, tsuas yog paub qhov loj ntawm thaj chaw ntawm daim ntaub iav thiab qhov sib npaug tuab (ib txheej ntawmiavcov fiberdaim ntaub sib npaug rau qhov tuab ntawm cov khoom), koj tuaj yeem xam qhov ntau ntawm cov resin uas muaj nyob hauv FRP

B xam los ntawm kev xam qhov hnyav ntawm cov khoom ua ntej thiab txiav txim siab feem pua ntawm cov ntsiab lus ntawm cov iav fiber loj.

(3)Iavcov fiberdaim ntaub nplaum system

Cov khoom uas muaj txheej gelcoat, gelcoat tsis tuaj yeem sib xyaw nrog cov khoom tsis huv, muab tshuaj txhuam ua ntej lub kaw lus yuav tsum tiv thaiv kev ua qias tuaj ntawm txheej gelcoat thiab txheej thaub qab, yog li ntawd kom tsis txhob ua rau muaj kev sib txuas tsis zoo ntawm cov khaubncaws sab nraud povtseg, thiab cuam tshuam rau qhov zoo ntawm cov khoom. Cov txheej gel txheej tuaj yeem txhim kho nrogntodaim lev. Lub kaw lus nplaum yuav tsum tau them sai sai rau cov resin impregnation ntawm cov iav fibers, ua ntej ua kom cov resin infiltration ntawm tag nrho cov nplaim ntawm cov fiber bundle, thiab tom qab ntawd ua rau huab cua hauv cov fiber bundle hloov pauv tag nrho los ntawm resin. Nws yog ib qho tseem ceeb heev kom ntseeg tau tias thawj txheej ntawm cov khoom siv reinforcing yog impregnated tag nrho nrog resin thiab haum ze, tshwj xeeb tshaj yog rau qee cov khoom siv hauv qhov kub siab dua. Impregnation tsis zoo thiab lamination tsis zoo tuaj yeem tso cua nyob ib puag ncig txheej gelcoat, thiab cov huab cua no tshuav tom qab tuaj yeem ua rau muaj cua npuas thaum lub sijhawm kho thiab siv cov khoom vim yog thermal nthuav dav.

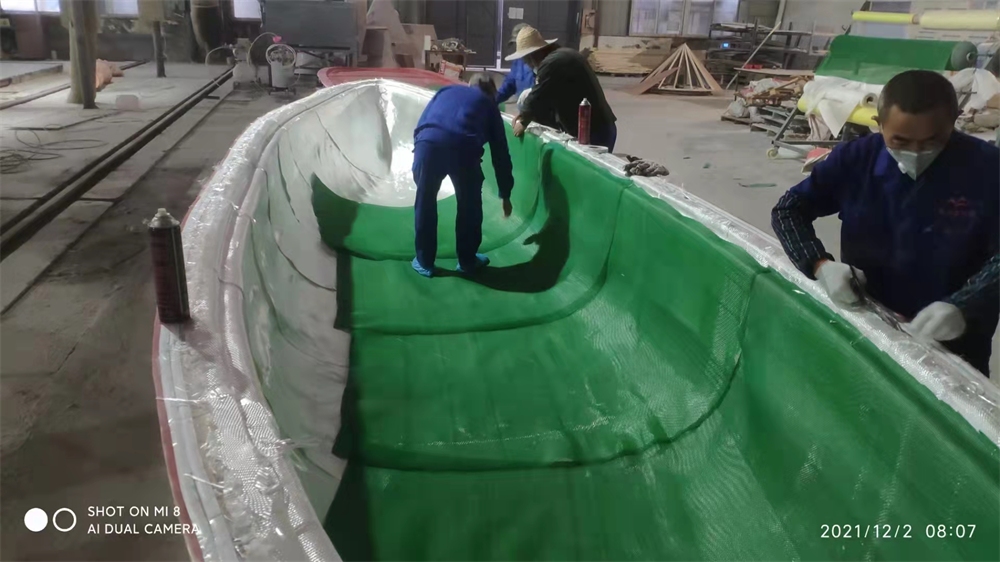

Tes-tso system, ua ntej hauv txheej gel txheej lossis pwm tsim nto nrog txhuam, scraper lossis impregnation roller thiab lwm yam cuab yeej tes muab tshuaj txhuam sib npaug nrog ib txheej ntawm cov resin npaj, thiab tom qab ntawd tso ib txheej ntawm cov ntaub ntawv txiav reinforcing (xws li diagonal strips, nyias daim ntaub lossis qhov chaw xav, thiab lwm yam), ua raws li cov cuab yeej tsim yuav raug txhuam tiaj tus, nias, kom nws haum ze, thiab them sai sai rau qhov tsis suav nrog cov pa npuas, yog li ntawd daim ntaub iav tag nrho impregnated, tsis yog ob lossis ntau txheej ntawm cov ntaub ntawv reinforcing tib lub sijhawm Tso. Rov ua qhov kev ua haujlwm saum toj no, kom txog thaum lub thickness xav tau los ntawm tus tsim.

Yog tias qhov geometry ntawm cov khoom nyuaj dua, qee qhov chaw uas cov khoom siv reinforcing tsis tau muab tso tiaj tus, cov npuas dej tsis yooj yim rau kev tshem tawm, cov txiab tuaj yeem siv los txiav qhov chaw thiab ua kom nws tiaj tus, nws yuav tsum tau sau tseg tias txhua txheej yuav tsum tau staggered qhov chaw ntawm qhov txiav, yog li ntawd kom tsis txhob ua rau poob zog.

Rau cov khoom nrog lub kaum sab xis, tuaj yeem sau nrogiav fiber thiab cov khoom siv resin. Yog tias qee qhov ntawm cov khoom loj heev, tuaj yeem ua kom tuab lossis txhawb nqa hauv thaj chaw kom ua tau raws li qhov yuav tsum tau siv.

Raws li cov ntaub fiber ntau qhov kev taw qhia txawv, nws lub zog kuj muaj qhov sib txawv. Qhov kev taw qhia ntawm cov ntaubcov ntaub iav fibersiv thiab txoj kev tso yuav tsum ua raws li cov txheej txheem xav tau.

(4) kev ua cov xov sib txuas

Tib txheej ntawm cov fibers li txuas ntxiv mus li sai tau, tsis txhob txiav lossis spliced tsis raws cai, tab sis vim qhov loj ntawm cov khoom, qhov nyuaj thiab lwm yam laj thawj ntawm cov kev txwv kom ua tiav, lub kaw lus muab tshuaj txhuam tuaj yeem coj thaum lub pob tw tso, lub lap seam yuav tsum tau staggered kom txog thaum cov tshuaj txhuam mus rau qhov tuab uas cov khoom xav tau. Thaum gluing, cov resin yog impregnated nrog cov cuab yeej xws li txhuam, rollers thiab npuas rollers thiab cov pa npuas raug drained.

Yog tias qhov xav tau lub zog siab, txhawm rau kom ntseeg tau tias lub zog ntawm cov khoom, lub pob qij txha yuav tsum tau siv ntawm ob daim ntaub, qhov dav ntawm lub pob qij txha yog li 50 hli. tib lub sijhawm, lub pob qij txha ntawm txhua txheej yuav tsum tau staggered ntau li ntau tau.

(3)Kev tso tesntawmtxoj hlua txiav daim levs

Thaum siv cov ntaub luv luv ua cov khoom siv txhawb nqa, nws yog qhov zoo tshaj plaws los siv ntau qhov ntau thiab tsawg ntawm cov menyuam impregnation rau kev ua haujlwm, vim tias cov menyuam impregnation muaj txiaj ntsig zoo hauv kev tshem tawm cov npuas hauv cov resin. Yog tias tsis muaj cov cuab yeej zoo li no thiab qhov impregnation yuav tsum tau ua los ntawm txhuam, cov resin yuav tsum tau siv los ntawm txoj kev txhuam taw tes, txwv tsis pub cov fibers yuav raug messed thiab dislocated kom qhov kev faib tawm tsis sib xws thiab qhov tuab tsis zoo ib yam. Cov khoom siv txhawb nqa tso rau hauv lub ces kaum tob sab hauv, yog tias txhuam lossis cov menyuam impregnation nyuaj rau ua kom nws haum ze, nws tuaj yeem du thiab nias los ntawm tes.

Thaum muab cov khoom tso rau, siv lub tshuab nplaum nplaum los nplaum cov kua nplaum rau ntawm qhov chaw ntawm cov pwm, tom qab ntawd muab cov lev txiav tso rau ntawm tes. daim ntawm lub pwm thiab ua kom du, tom qab ntawd siv lub menyuam roj nplaum rau ntawm cov kua nplaum, dov rov qab thiab rov qab, kom cov kua nplaum resin raug muab tso rau hauv daim lev, tom qab ntawd siv lub menyuam roj nplaum npuas los nias cov kua nplaum sab hauv daim lev rau ntawm qhov chaw thiab tso cov pa npuas tawm, tom qab ntawd nplaum txheej thib ob. Yog tias koj ntsib lub ces kaum, koj tuaj yeem rhuav daim lev los ntawm tes kom yooj yim rau kev qhwv, thiab lub voj voog ntawm ob daim lev yog li 50 hli.

Ntau yam khoom kuj tseem siv taucov ntaub pua plag txiavthiab cov ntaub iav fiber ntau lwm txheej, xws li cov tuam txhab Nyiv Pooj muab tshuaj txhuam lub nkoj nuv ntses yog siv lwm txoj kev muab tshuaj txhuam, nws tau tshaj tawm tias txoj kev tsim cov khoom FRP nrog kev ua tau zoo.

(6) Lub kaw lus nplaum ntawm cov khoom tuab-phab ntsa

Cov khoom tuab hauv qab 8 hli tuaj yeem tsim tau ib zaug, thiab thaum cov khoom tuab ntau dua 8 hli, yuav tsum muab faib ua ntau qhov molding, txwv tsis pub cov khoom yuav kho tau vim yog qhov cua sov tsis zoo ua rau kub hnyiab, hloov xim, cuam tshuam rau kev ua haujlwm ntawm cov khoom. Rau cov khoom uas muaj ntau qhov molding, cov burrs thiab cov npuas tsim tom qab thawj zaug nplaum kho yuav tsum tau muab tshem tawm ua ntej txuas ntxiv nplaum rau txoj kev tom ntej. Feem ntau hais lus, nws raug pom zoo tias qhov tuab ntawm ib qho molding yuav tsum tsis pub tshaj 5 hli, tab sis kuj tseem muaj cov resins tso tawm cua sov tsawg thiab cov resins shrinkage tsawg tsim rau molding cov khoom tuab, thiab qhov tuab ntawm cov resin no loj dua rau ib qho molding.

Chongqing Dujiang Composites Co., Ltd.

Tiv tauj peb:

Email:marketing@frp-cqdj.com

WhatsApp: +8615823184699

Xov tooj: +86 023-67853804

Lub vas sab hauv internet:www.frp-cqdj.com

Lub sijhawm tshaj tawm: Lub Kaum Hli-09-2022