Kev Taw Qhia

Fiberglass rovingyog ib yam khoom tseem ceeb hauv kev tsim khoom sib xyaw, muab lub zog siab, yooj ywm, thiab tiv taus xeb. Txawm li cas los xij, xaiv ntawmkev rov qab ncaj qhathiabsib dhos rovingtuaj yeem cuam tshuam loj heev rau kev ua tau zoo ntawm cov khoom, tus nqi, thiab kev ua haujlwm zoo ntawm cov khoom.

Phau ntawv qhia no muab ob hom piv rau lwm hom, tshuaj xyuas lawv cov txheej txheem tsim khoom, cov khoom siv kho tshuab, kev siv, thiab kev siv nyiaj tsim nyog los pab koj xaiv qhov zoo tshaj plaws rau koj qhov project.

Fiberglass Roving yog dab tsi?

Fiberglass roving muaj cov iav txuas ntxiv uas sib txuas ua ke rau kev txhawb nqa hauv cov khoom sib xyaw. Nws siv dav hauv:

Pultrusion & filament winding

Cov tshuaj molding compound (SMC)

Lub cev nkoj thiab cov khoom siv tsheb

Cov hniav cua turbine

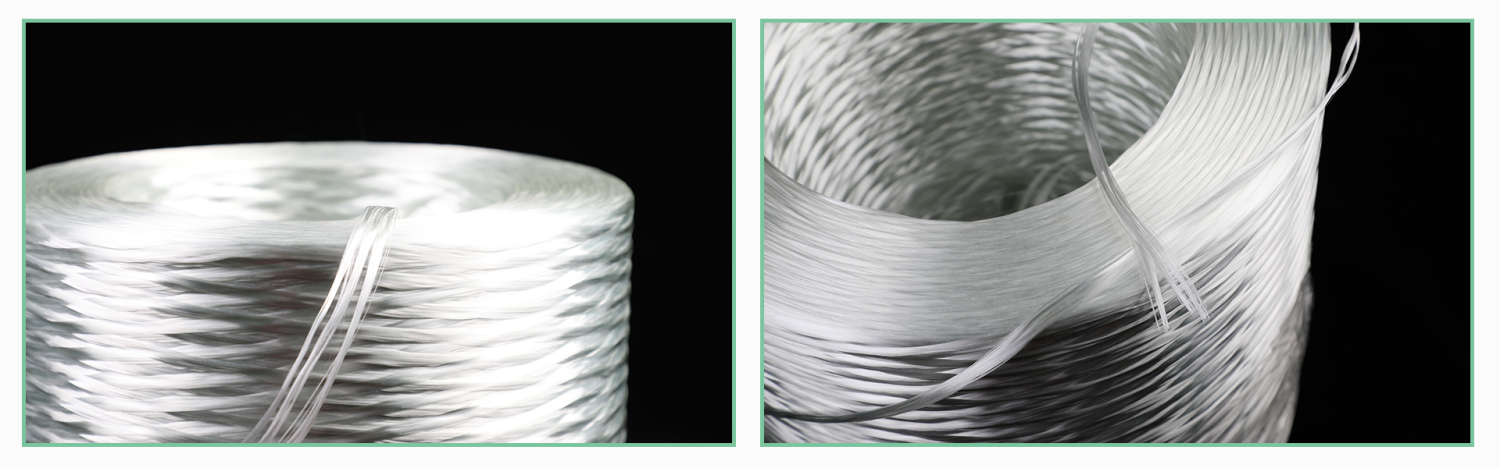

Fiberglass rovingmuaj ob hom tseem ceeb:kev rov qab ncaj qhathiabsib dhos roving, txhua tus muaj qhov zoo sib txawv.

Kev Roving Ncaj Qha: Cov Nta thiab Cov Txiaj Ntsig

Cov Txheej Txheem Tsim Khoom

Fiberglass dkev mus ncig ncaj qhayog tsim los ntawm kev rub cov iav uas yaj ncaj qha mus rau hauv cov filaments, uas tom qab ntawd raug qhwv rau hauv ib pob yam tsis muaj kev sib ntswg. Txoj kev no ua kom ntseeg tau tias:

✔ Lub zog tensile siab dua (vim yog qhov kev puas tsuaj tsawg kawg nkaus ntawm cov filament)

✔ Kev sib raug zoo ntawm cov resin zoo dua (sib xws li ntub dej)

✔ Kev siv nyiaj tsawg dua (cov kauj ruam ua tiav tsawg dua)

Cov txiaj ntsig tseem ceeb

Cov khoom siv kho tshuab zoo tshaj plaws -Zoo tagnrho rau cov ntawv thov kev ntxhov siab xws li aerospace thiab cov hlab ntsha siab.

Kev ua haujlwm sai dua ntawm cov khoom tsim tawm -Nyiam siv rau hauv cov txheej txheem tsis siv neeg xws li pultrusion.

Kev tsim cov fuzz qis dua -Txo cov khoom siv hnav hauv kev txhaj tshuaj.

Cov Ntawv Thov Feem Ntau

Cov qauv pultruded (fiberglass beams, rods)

Cov thoob dej thiab cov kav dej uas muaj filament

Cov nplooj ntoos hlav tsheb

Kev Sib Dhos Roving: Cov Nta thiab Cov Txiaj Ntsig

Cov Txheej Txheem Tsim Khoom

Fiberglass asib sau ua ke roving yog ua los ntawm kev sib sau ua ke ntau txoj xov me me thiab muab lawv ua ke. Cov txheej txheem no tso cai rau:

✔ Kev tswj hwm zoo dua ntawm kev ncaj ncees ntawm cov xov

✔ Kev tswj hwm zoo dua hauv cov txheej txheem tes

✔ Ntau qhov kev ywj pheej hauv kev faib qhov hnyav

Cov txiaj ntsig tseem ceeb

Yooj yim dua rau kev txiav thiab tuav -Zoo dua rau kev siv tes thiab tshuaj tsuag.

Zoo dua rau cov duab sib xyaw -Siv rau hauv lub nkoj hulls thiab lub dab da dej molding.

Tus nqi qis dua rau kev tsim khoom me me -Haum rau cov chaw ua haujlwm uas muaj kev tswj hwm tsis siv neeg tsawg.

Cov Ntawv Thov Feem Ntau

Kev tsim nkoj thiab cov khoom sib xyaw hauv hiav txwv

Cov khoom siv hauv chav dej (dab da dej, da dej)

Kev cai FRP qhov chaw

Kev Roving Ncaj Qha vs. Kev Sib Dhos: Qhov Txawv Tseem Ceeb

| Qhov tseem ceeb | Kev Rov Qab Ncaj Qha | Sib dhos Roving |

| Lub zog | Lub zog tensile siab dua | Qis me ntsis vim yog kev sib sau ua ke |

| Cov Resin Wet-Out | Sai dua, sib xws dua | Tej zaum yuav xav tau ntau cov resin |

| Kev Ceev Ntau Lawm | Sai dua (ua haujlwm tau yooj yim) | Qis dua (cov txheej txheem tes) |

| Tus nqi | Qis dua (kev tsim khoom zoo) | Siab dua (kev ua ntxiv) |

| Zoo Tshaj Plaws Rau | Pultrusion, filament winding | Muab tso rau tes, txau tshuaj |

Koj Yuav Tsum Xaiv Qhov Twg?

Thaum Twg Yuav Tsum Siv Direct Roving

✅ Kev tsim khoom ntau (piv txwv li, cov khoom siv hauv tsheb)

✅ Cov ntawv thov uas xav tau lub zog siab tshaj plaws (piv txwv li, cov hniav cua turbine)

✅ Cov txheej txheem tsim khoom siv tshuab

Thaum Twg Yuav Tsum Siv Assembled Roving

✅ Kev tsim khoom raws li kev cai lossis kev tsim khoom me me (piv txwv li, kho nkoj)

✅ Cov txheej txheem tsim khoom siv tes (piv txwv li, cov duab puab FRP kos duab)

✅ Tej yaam num uas xav tau kev txiav thiab kev tuav yooj yim

Cov Qauv Kev Lag Luam & Kev Pom Zoo Yav Tom Ntej

Lub ntiaj tebfiberglass rovingkev lag luam kwv yees tias yuav loj hlob ntawm 5.8% CAGR (2024-2030) vim muaj kev thov nce ntxiv hauv lub zog cua, kev siv lub tsheb kom sib dua, thiab kev tsim kho vaj tse. Cov kev tsim kho tshiab xws li kev roving uas zoo rau ib puag ncig (iav rov ua dua tshiab) thiab kev rovings ntse (cov sensors uas muab tso rau hauv) yog cov qauv tshiab.

Xaus lus

Xaiv ntawm ncaj qha thiabsib dhos rovingnyob ntawm koj txoj kev tsim khoom, peev nyiaj, thiab kev xav tau kev ua tau zoo.Kev rov qab ncaj qhazoo heev hauv kev siv ceev ceev, muaj zog, thaum sib sau ua ke zoo dua rau kev siv tes, kev tsim khoom raws li kev cai.

Xav tau cov lus qhia los ntawm cov kws tshaj lij? Sab laj nrog tus neeg muag khoom fiberglass kom phim hom roving uas haum rau koj qhov project.

Lub sijhawm tshaj tawm: Tsib Hlis-06-2025