Kev Taw Qhia

Fiberglass roving yog cov khoom siv tseem ceeb hauv cov khoom sib xyaw, tab sis xaiv ntawmkev rov qab ncaj qha thiabsib dhos roving tuaj yeem cuam tshuam loj heev rau kev ua tau zoo, tus nqi, thiab kev tsim khoom zoo. Qhov kev sib piv tob no tshawb nrhiav lawv qhov sib txawv, qhov zoo, thiab cov ntawv thov zoo tshaj plaws los pab koj xaiv qhov yog.

Fiberglass Direct Roving yog dab tsi?

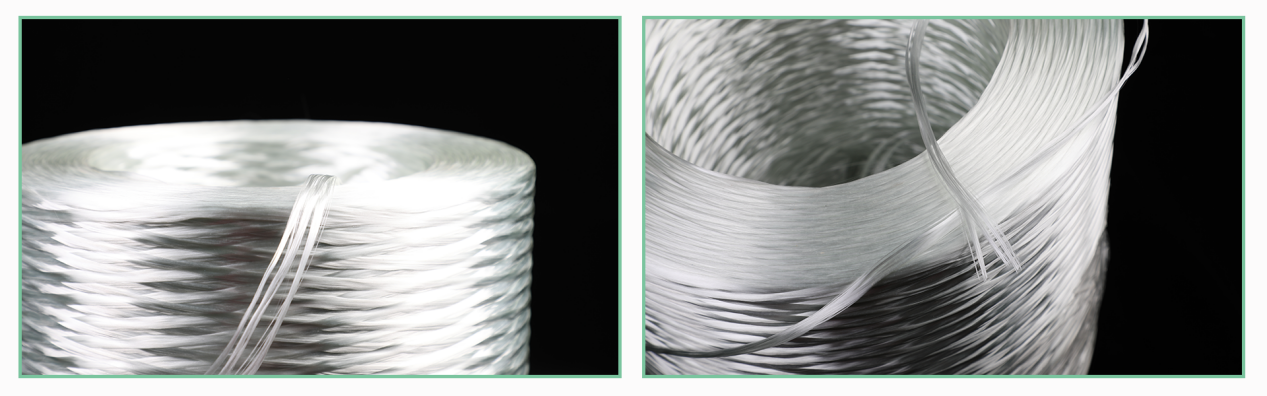

Fiberglass direct roving yog tsim los ntawm kev rub cov iav txuas ntxiv mus ncaj qha los ntawm lub cub tawg, tom qab ntawd muab lawv khi ua cov xov tsis muaj kev sib ntswg. Cov kev rovings no raug qhwv rau ntawm bobbins, kom ntseeg tau tias muaj qhov tuab sib npaug thiab lub zog tensile siab.

Cov Nta Tseem Ceeb:

✔Qhov sib piv ntawm lub zog siab rau qhov hnyav

✔Kev sib raug zoo ntawm cov resin zoo heev (sai ntub tawm)

✔Kev sib dhos ua ke ntawm cov filament (cov khoom siv kho tshuab zoo dua)

✔Zoo tagnrho rau cov txheej txheem tsis siv neeg (pultrusion, filament winding)

Fiberglass Assembled Roving yog dab tsi?

Sib dhos roving yog ua los ntawm kev sib sau ua ke ntau txoj xov me me (feem ntau ntswj) ua ib pob loj dua. Cov txheej txheem no tuaj yeem ua rau muaj qhov sib txawv me ntsis ntawm qhov tuab tab sis txhim kho kev tuav hauv qee qhov kev siv.

Cov Nta Tseem Ceeb:

✔Zoo dua drapeability (pab tau rau tes pw)

✔Txo cov fuzz tsim (kev tuav huv dua)

✔Ntau dua yooj ywm rau cov pwm nyuaj

✔Feem ntau pheej yig dua rau cov txheej txheem tes

Kev Roving Ncaj Qha vs. Kev Roving Sib Dhos: Qhov Txawv Tseem Ceeb

| Qhov tseem ceeb | Kev Rov Qab Ncaj Qha | Sib dhos Roving |

| Kev Tsim Khoom | Cov filaments kos ncaj qha | Muaj ntau cov strands sib xyaw ua ke |

| Lub zog | Lub zog tensile siab dua | Me ntsis qis dua vim yog qhov twists |

| Cov Resin Wet-Out | Kev nqus dej sai dua | Qis dua (kev sib ntswg ua rau cov roj hmab tsis ua haujlwm) |

| Tus nqi | Siab dua me ntsis | Pheej yig dua rau qee qhov kev siv |

| Zoo Tshaj Plaws Rau | Pultrusion, filament winding | Muab tso rau tes, txau tshuaj |

Koj Yuav Tsum Xaiv Qhov Twg?

Thaum Twg Yuav SivFiberglass Ncaj Qha Roving

✅Cov khoom sib xyaw ua ke ua tau zoo (cov hniav cua tshuab, aerospace)

✅Kev tsim khoom tsis siv neeg (pultrusion, RTM, filament winding)

✅Cov ntawv thov uas xav tau lub zog siab tshaj plaws & kev tawv ncauj

Thaum Twg Yuav Tsum Siv Assembled Roving

✅Cov txheej txheem ua tes (tso tes, txau)

✅Cov pwm nyuaj uas xav tau kev ywj pheej

✅Cov haujlwm uas muaj kev cuam tshuam nrog tus nqi

Kev Siv Hauv Kev Lag Luam Piv Txwv

1. Kev Lag Luam Tsheb

Kev rov qab ncaj qha: Cov khoom siv hauv tsev (cov nplooj ntoos hlav, cov ntoo bumper)

Kev sib sau ua ke roving: Cov vaj huam sib luag sab hauv, cov khoom tsis yog cov qauv

2. Kev Tsim Kho thiab Kev Tsim Kho Vaj Tse

Kev rov qab ncaj qha: Rebar, choj reinforcements

Sib dhos roving: Cov vaj huam sib luag kho kom zoo nkauj, cov ntsej muag sib dua

3. Tub Rog thiab Huab Cua

Kev ncig ncaj qha: Lub cev nkoj, cov khoom siv dav hlau (xav tau lub zog siab)

Kev sib dhos ua ke: Cov khoom me me ntawm lub nkoj, cov ntaub sab hauv

Cov Kws Tshaj Lij Cov Lus Qhia & Cov Qauv Lag Luam

Raws li John Smith, Tus Kws Ua Haujlwm Composites ntawm Owens Corning:

"Kev rov qab ncaj qha tswj hwm kev tsim khoom tsis siv neeg vim nws qhov sib xws, thaum kev sib sau ua ke tseem nrov hauv cov txheej txheem tes uas qhov kev ywj pheej yog qhov tseem ceeb."

Cov Ntaub Ntawv Lag Luam:

Kev lag luam fiberglass roving thoob ntiaj teb kwv yees tias yuav loj hlob ntawm 6.2% CAGR (2024-2030).

Kev rov qab ncaj qha Qhov kev thov nce ntxiv vim muaj kev siv tshuab ntau ntxiv hauv lub zog cua thiab kev lag luam tsheb.

Xaus Lus: Qhov Twg Yeej?

Nyob ntawd'tsis muaj universal"zoo dua"kev xaiv—nws nyob ntawm koj qhov project's xav tau:

Rau lub zog siab & automation→Kev rov qab ncaj qha

Rau kev ua haujlwm tes thiab txuag nqi→Sib dhos roving

Los ntawm kev nkag siab txog cov qhov sib txawv no, cov chaw tsim khoom tuaj yeem ua kom zoo dua qhov kev ua tau zoo, txo cov khib nyiab, thiab txhim kho ROI hauv kev tsim khoom sib xyaw.

Lub sijhawm tshaj tawm: Lub Xya Hli-10-2025