Kev lag luam thoob ntiaj teb composites txuas ntxiv hloov zuj zus, nrog rau cov ntaub ntawv ua tau zoo ua lub hauv paus ntawm kev lag luam tsheb, aerospace, thiab lub zog rov ua dua tshiab. Hauv plawv ntawm qhov kev hloov pauv no yogfiberglass rovingTxawm koj koom nrog pultrusion, filament winding, lossis cov txheej txheem tsuag, qhov zoo ntawm kojiav fiber rovingncaj qha qhia txog kev ruaj khov ntawm cov qauv thiab lub neej ntev ntawm cov khoom tiav.

Kev xaiv tus khub zoo tsis yog tsuas yog saib daim ntawv teev khoom xwb; nws yuav tsum tau kawm txog cov lus qhia txog kev siv tshuab, kev tsim khoom sib xws, thiab kev xa khoom. Hauv qab no yog xya yam tseem ceeb uas koj yuav tsum soj ntsuam thaum xaiv ib qho tus neeg muag khoom iav roving.

1. Cov Khoom Siv Qib thiab Cov Tshuaj Lom Zem

Kauj ruam thawj zaug hauv kev ntsuam xyuas yog txiav txim siab seb hom iav twg uas tus neeg muag khoom muab. Cov tshuaj lom neeg sib xyaw ntawm cov iav cuam tshuam txhua yam los ntawm lub zog tensile mus rau kev tiv thaiv acid.

E Iav Roving:Tus qauv kev lag luam.E iav rovingmuab kev rwb thaiv hluav taws xob zoo heev thiab lub zog kho tshuab. Nws yog qhov kev daws teeb meem pheej yig tshaj plaws rau cov khoom sib xyaw ua ke dav dav.

E Iav Ncaj Qha Roving:Ib qho version zoo dua ntawm E-iav,e iav ncaj qha rovingyog tsim los rau cov ntawv thov siab-nqes xws li pultrusion, qhov twg cov filament txoj kab uas hla sib xws yog qhov tseem ceeb.

S Iav Roving:Thaum xav tau kev ua haujlwm siab heev,s iav roving(iav muaj zog siab) yog qhov kev xaiv. Nws muab lub zog tensile thiab modulus siab dua piv rau E-iav, txawm hais tias ntawm tus nqi fiberglass roving siab dua.

| Vaj tse | E-iav | S-Iav |

| Lub zog Tensile (MPa) | ~3,400 | ~4,800 |

| Modulus Elastic (GPa) | ~72 | ~86 |

| Kev Tiv Thaiv Kub | Nruab nrab | Siab |

2. Kev Tsim Khoom: Kev Thauj Mus Los Ncaj Qha piv rau Kev Sib Dhos

Nkag siab txog qhov txawv ntawmkev rov qab ncaj qhathiabfiberglass sib dhos rovingyog qhov tseem ceeb rau koj txoj kab ntau lawm.

Fiberglass Ncaj Qha Roving:Qhov no muaj ib txoj hlua ntawm cov filaments txuas ntxiv mus. Nws yog qhov nyiam rau filament winding thiab pultrusion vim nws muaj lub zog siab thiab zoo heev resin wet-out.

Fiberglass Sib Dhos Roving:Kuj tseem hu ua multi-end roving, qhov no yog tsim los ntawm kev sib sau ua ke ntau txoj hlua me me rau hauv ib pob. Nws feem ntau yog siv rau kev txiav cov ntawv thov, xws li SMC (Sheet Molding Compound) lossis centrifugal casting.

Ib tus neeg muag khoom uas muaj ntau yam kev xaiv yuav tsum muab ob qho tib si, suav nrog cov kws tshwj xeebfiberglass roving tas mus licov kev xaiv uas ua kom tsis muaj kev tawg thaum lub sijhawm ua haujlwm ceev ceev.

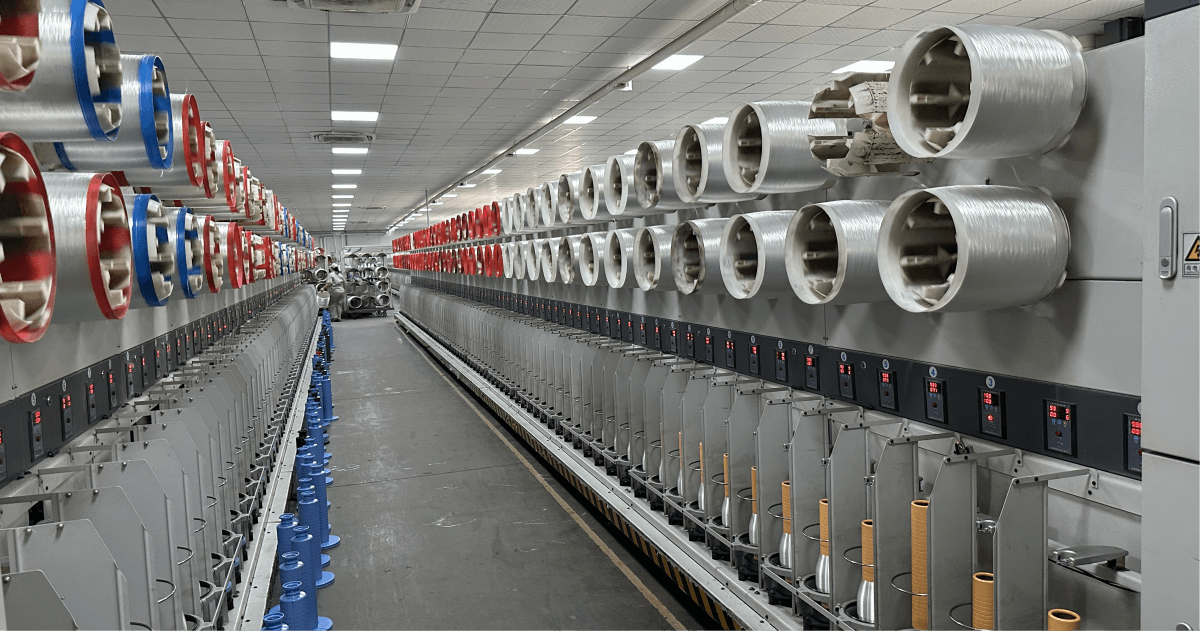

3.Kev Sib Xws ntawm Cov Txheej Txheem: Qhov Tshwj Xeeb "Roving Phom"

Yog tias koj lub chaw siv cov txheej txheem txau, koj yuav tsum soj ntsuam tus neeg muag khoom lub fiberglass gun roving (tseem hu ua gun roving fiberglass). Tsis yog txhua lub rovings yog tsim los rau kev txiav.

Ib lub tshuab tua phom zoo yuav tsum muaj cov hauv qab no:

(1) Qis Static: Txhawm rau tiv thaiv cov fibers los ntawm lo rau ntawmphom fiberglass rovingthaum lub sijhawm ntawm kev txiav.

(2) Zoo heev Lay-flat: Cov xov txiav yuav tsum pw tiaj tus rau ntawm pwm yam tsis muaj "dhia rov qab."

(3) Kev ntub dej sai: Lub peev xwm ntawmfiberglass roving yobcov xov kom nqus cov resin sai sai ($ t < 30 vib nas this hauv kev sim txheem).

Yog tias tus neeg muag khoom tsis tuaj yeem muab cov ntaub ntawv ntawm "kev txiav tau" ntawm lawvphom fiberglass rovingcov ntaub ntawv, lawv yuav tsis yog tus khub zoo rau kev siv tshuaj tsuag.

4. Kev Sib Piv ntawm Cov Resin thiab Kev Ntsuas Chemistry

Qhov "sizing" yog ib qho tshuaj pleev xim siv rauiav fiber rovingthaum lub sijhawm tsim khoom. Nws ua haujlwm ua tus choj ntawm lub iav thiab cov resin. Koj yuav tsum xyuas kom meej tias tus neeg muag khoom qhov loj me sib xws nrog koj lub kaw lus resin tshwj xeeb (Polyester,Vinyl Ester, los yog Epoxy).

Cov Lus Qhia Zoo:Qhov loj tsis sib xws tuaj yeem ua rau tawg ua tej daim me me. Ib txwm thov kom muaj "Daim Ntawv Qhia Txog Qhov Loj Sib Xws." Piv txwv li, ibfiberglass direct rovingoptimized rau epoxy yuav ua tsis tau zoo hauv cov txheej txheem pultrusion polyester.

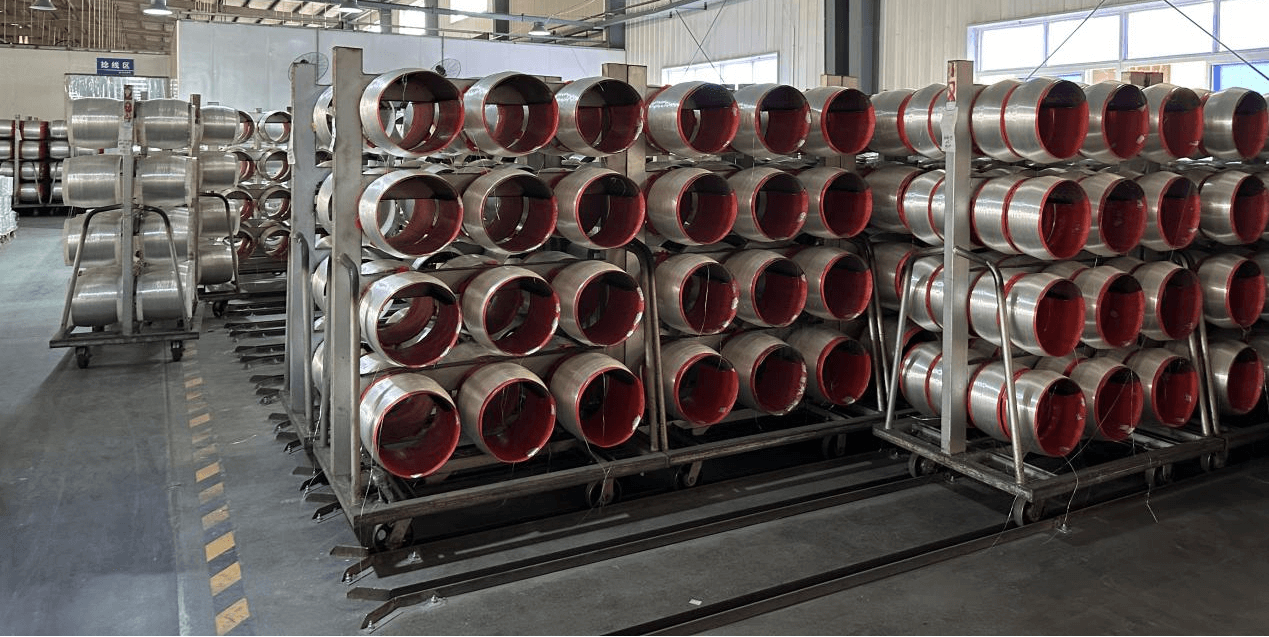

5. Kev Tsim Khoom Sib Xws thiab Kev Zoo ntawm Yob

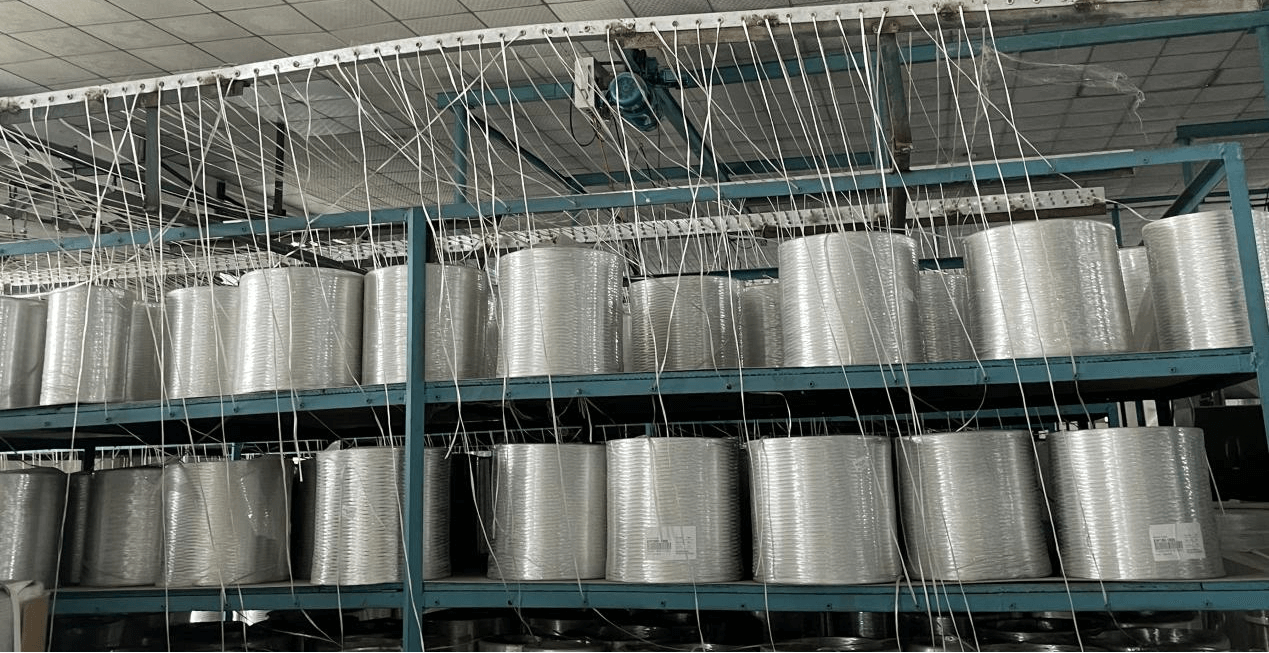

Thaum koj tau txais ib qhofiberglass roving yob, nws lub cev nqaij daim tawv qhia tau ntau yam txog kev tswj xyuas zoo ntawm tus neeg muag khoom. Saib cov hauv qab no:

Kev Ntsuas Qhov Ceev Tawm:Yuav kom ntseeg tau tias muaj kev sib npaug ntawm cov qauv hauv qhov kawg composite, cov fiber's linear mass (Tex/Yield) yuav tsum muaj kev ruaj khov zoo heev, nrog rau kev hloov pauv txwv tsis pub dhau ntawm ± 5% variance los ntawm cov lus qhia nominal.

Catenary:Txhua txoj hlua hauv qhov roving yuav tsum muaj kev sib npaug zos kom tsis txhob sagging thaum lub sijhawm ua tiav.

Kev Tshem Tawm Sab Hauv vs. Kev Tshem Tawm Sab Nraud:Xyuas kom meej tiasfiberglass roving yobunwinds du thiab tsis muaj knotting, uas tuaj yeem ua rau lub tshuab downtime.

6. Kev soj ntsuam tus nqi "Fiberglass Roving" piv rau tus nqi tag nrho

Thaum lubfiberglass roving nqeyog ib qho tseem ceeb hauv kev yuav khoom, nws yuav tsum tsis txhob yog tib qho xwb. Kev mus ncig pheej yig feem ntau ua rau:

Cov khib nyiab ntau dua vim yog fuzz (fiber breakage).

Kev siv cov resin ntau ntxiv (qhov ntub dej tsis zoo).

Tej zaum cov khoom tsis ua haujlwm thiab lub luag haujlwm.

Thaum piv cov nqi, xam covTag Nrho Tus Nqi ntawm Kev Muaj Tswv (TCO). Ib qho kim dua me ntsise iav ncaj qha rovinguas txo koj cov khoom pov tseg los ntawm 10% yog qhov kev xaiv pheej yig dua.

7. Kev Tshawb Fawb thiab Kev Txhim Kho ntawm Tus Neeg Muab Khoom thiab Kev Txhawb Nqa Kev Txawj Ntse

Thaum kawg, ntsuam xyuas lub peev xwm ntawm tus neeg muag khoom los tsim kho tshiab. Puas yog lawv tab tom tsim cov tshiabfiberglass roving tas mus licov thev naus laus zis los txo qhov hnyav? Lawv puas tuaj yeem pab koj daws teeb meem nrog kojkev taug kev phomcov qauv tsuag?

Ib tug neeg muag khoom uas ntseeg tau ua haujlwm ua tus khub. Lawv yuav tsum muab cov hauv qab no:

CoA (Daim Ntawv Pov Thawj Kev Tshawb Fawb): Rau txhua pawg.

Kev Txhawb Nqa Hauv Tsev: Txhawm rau txhim kho koj cov tshuab rau lawv cov kev tshwj xeebfiberglass roving.

Kev Kho Kom Haum: Lub peev xwm los kho Tex lossis sizing rau cov haujlwm tshwj xeeb.

Xaus lus

Xaiv qhov yogfiberglass roving neeg muag khoomyog ib qho kev txiav txim siab zoo uas cuam tshuam rau koj qhov kev ua haujlwm zoo thiab cov khoom zoo. Los ntawm kev tsom mus rau cov qib khoom siv (xws lie iav roving), cov kev xav tau tshwj xeeb rau cov txheej txheem (xws likev taug kev phom), thiab qhov kev ncaj ncees tag nrho ntawmfiberglass direct roving, koj tuaj yeem ruaj ntseg ib txoj saw hlau uas txhawb nqa kev loj hlob mus sij hawm ntev.

Nco ntsoov, tus neeg muab khoom zoo tshaj plaws tsis yog tus uas muaj tus nqi qis tshaj xwbfiberglass roving nqe, tab sis tus uas nwsiav rovingthev naus laus zis sib txuas ua ke nrog koj lub hom phiaj tsim khoom.

Koj puas xav kom kuv tsim ib daim ntawv RFQ (Kev Thov Kom Tau Txais Nqe) uas koj siv tau los tshuaj xyuas koj cov neeg muab khoom fiberglass?

Yog tias koj xav tau, koj tuaj yeem tiv tauj kuv:

Email:marketing@frp-cqdj.com

WhatsApp: +8615823184699

Web: www.frp-cqdj.com

Lub sijhawm tshaj tawm: Lub Ib Hlis-23-2026