Kev Nug Txog Pricelist

Yog tias koj muaj lus nug txog peb cov khoom lossis daim ntawv teev nqi, thov tawm koj tus email rau peb thiab peb yuav tiv tauj koj tsis pub dhau 24 teev.

Kev rov qab ncaj qha yog tsim nrog cov tex lossis cov zis uas tau txhais meej thiab feem ntau yog siv ua cov khoom siv rau cov txheej txheem weaving. Nws muab kev yooj yim unwinding vim yog qhov nro txawm, tsim cov fuzz tsawg, thiab zoo heev wettability. Nws kuj tseem siv tau rau hauv ntau yam txheej txheem txheej txheem xws li pultrusion lossis filament winding.

Kev rov qab ncaj qharaug kho nrog silane-raws li sizing thaum lub sijhawm tsim khoom kom ntseeg tau tias muaj kev sib raug zoo nrog thermosets xws li UP (unsaturated polyester), VE (vinyl ester), thiab epoxy resins. Kev kho mob no tso cai raukev rov qab ncaj qhakom pom cov khoom siv kho tshuab zoo thiab tshuaj lom neeg tsis kam, ua rau nws haum rau ntau yam kev siv.

Fiberglass direct rovingyog ib hom kev roving ib zaug kawg ua los ntawm E-Glass, uas muaj ntau yam khoom tseem ceeb.

1. Cov khoom no suav nrog kev tsis muaj splice, tsis muaj catenary, thiab muaj cov khoom zoo warping thiab weaving hauv ob qho tib si warp thiab sau cov lus qhia.

2. Nws yooj yim rau impregnate vim tsis muaj twist. Muaj ntau qhov loj me sib txawv, txhua tus muaj cov yam ntxwv tshwj xeeb xws li sib xws zoo heev nrog ntau yam resins thiab tiv taus alkaline ib puag ncig.

3.Kev ncig teb chawskuj muaj cov txiaj ntsig xws li kev ua kom sov tsawg, tiv taus hluav taws, sib xws nrog cov organic matrices, rwb thaiv hluav taws xob, thiab kev ruaj khov ntawm qhov ntev.

4. Nws tsis haum rau kev siv kub siab thiab tsis yog biodegradable. Txhawm rau daws cov teeb meem no, cov chaw tsim khoom tuaj yeem ntxiv lwm cov ntaub ntawv lossis cov khoom ntxiv rau hauv cov khoom sib xyaw ua ke kom txhim kho kev tiv thaiv kev cuam tshuam thiab kev tawv, txhim kho kev sib txuas ntawm fiber-matrix, thiab ua kom muaj zog interfacial shear.

5.Fiberglass direct rovingmuaj ntau yam zoo heev.

Nrhiav ib qho chaw txhim khu kev qha ntawmFiberglass direct rovingTsis txhob nrhiav ntxiv lawm! PebFiberglass direct rovingyog tsim los ntawm kev siv cov thev naus laus zis siab heev thiab cov ntaub ntawv zoo, ua kom muaj kev ua tau zoo thiab ua haujlwm ntev. Tsim los rau ntau yam kev siv, pebFiberglass direct rovingmuaj cov khoom zoo heev uas ntub tawm, ua kom cov resin impregnation zoo tshaj plaws rau kev txhim kho lub zog thiab kev nruj. Txawm hais tias koj xav tau nws rau kev tsim khoom sib xyaw, pultrusion, filament winding, lossis lwm yam kev siv, pebFiberglass direct rovingyog qhov kev xaiv zoo tshaj plaws. Tiv tauj peb hnub no kom paub ntau ntxiv txog pebFiberglass direct rovingthiab tshawb nrhiav seb nws tuaj yeem tsa koj cov txheej txheem tsim khoom mus rau qib siab tshiab li cas.

Lub fiberglass direct rovingua rau pom kev ua haujlwm zoo thiab tsis muaj fuzz, ua rau nws haum rau cov ntawv thov xws li FRP tanks, cooling towers, model props, lighting tile sheds, nkoj, auto accessories, environmental protection projects, new ru tsev building materials, bathtubs, thiab ntau ntxiv. Nws muaj kev tiv thaiv acid corrosion zoo heev, tiv thaiv kev laus, thiab cov khoom siv kho tshuab, ua rau nws yog cov khoom siv txhim khu kev qha rau ntau yam kev lag luam thiab kev tsim kho.

Ntxiv rau nws cov khoom siv kho tshuab, qhov kev roving ncaj qha yog sib xws nrog ntau lub tshuab resin, ua kom tiav thiab sai sai ntub tawm. Qhov no ua rau nws tsim nyog rau kev siv hauv cov txheej txheem txheej txheem sib txawv, xws li pultrusion lossis filament winding. Cov ntawv thov sib xyaw ua ke kawg ntawmfiberglass direct rovingtuaj yeem pom muaj nyob rau hauv kev tsim kho vaj tse, kev tsim kho, kev ua si nawv thiab kev lom zem, thiab kev thauj mus los hauv dej.

Zuag qhia tag nrho,fiberglass direct rovingyog ib yam khoom siv ntau yam uas pom tau tias muaj kev siv ntau yam lag luam thiab cov khoom vim nws muaj kev sib raug zoo nrog ntau hom resin systems, cov khoom siv zoo heev, thiab kev tiv taus corrosion thiab kev laus.

| Hom iav | E6-fiberglass ncaj qha roving | ||||||||

| Hom Loj | Silane | ||||||||

| Tus lej loj | 386T | ||||||||

| Kev Ceev Nruag(ntawv xov xwm) | 300 | 200 400 | 200 600 | 735 900 | 1100 1200 | 2000 xyoo | 2200 | 2400 4800 | 9600 |

| Txoj kab uas hla ntawm lub ntsiab lus (μm) | 13 | 16 | 17 | 17 | 17 | 21 | 22 | 24 | 31 |

| Qhov Ceev Tawm (%) | Cov ntsiab lus noo noo (%) | Qhov Loj Cov Ntsiab Lus (%) | Lub zog tawg (N/Tex ) |

| ISO 1889 | ISO3344 | ISO1887 | ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40 (≤2400tex) ≥0.35 (2401 ~ 4800tex) ≥0.30 (> 4800tex) |

| Cov Khoom Siv Kho Tshuab | Chav tsev | Tus nqi | Cov roj hmab | Txoj Kev |

| Lub zog tensile | MPa | 2660 | UP | ASTM D2343 |

| Modulus Tensile | MPa | 80218 | UP | ASTM D2343 |

| Lub zog txiav | MPa | 2580 | EP | ASTM D2343 |

| Modulus Tensile | MPa | 80124 | EP | ASTM D2343 |

| Lub zog txiav | MPa | 68 | EP | ASTM D2344 |

| Kev khaws cia lub zog txiav (72 teev rhaub) | % | 94 | EP | / |

Cov Lus Cim:Cov ntaub ntawv saum toj no yog cov nqi sim tiag tiag rau E6DR24-2400-386H thiab rau kev siv xwb.

| Qhov siab ntawm pob khoom mm (hauv) | 255(10) | 255(10) |

| Pob khoom sab hauv txoj kab uas hla mm (hauv) | 160 (6.3) | 160 (6.3) |

| Pob sab nraud txoj kab uas hla mm (hauv) | 280(11) | 310 (12.2) |

| Qhov hnyav ntawm pob khoom (kg) | 15.6 (34.4) | 22 (48.5) |

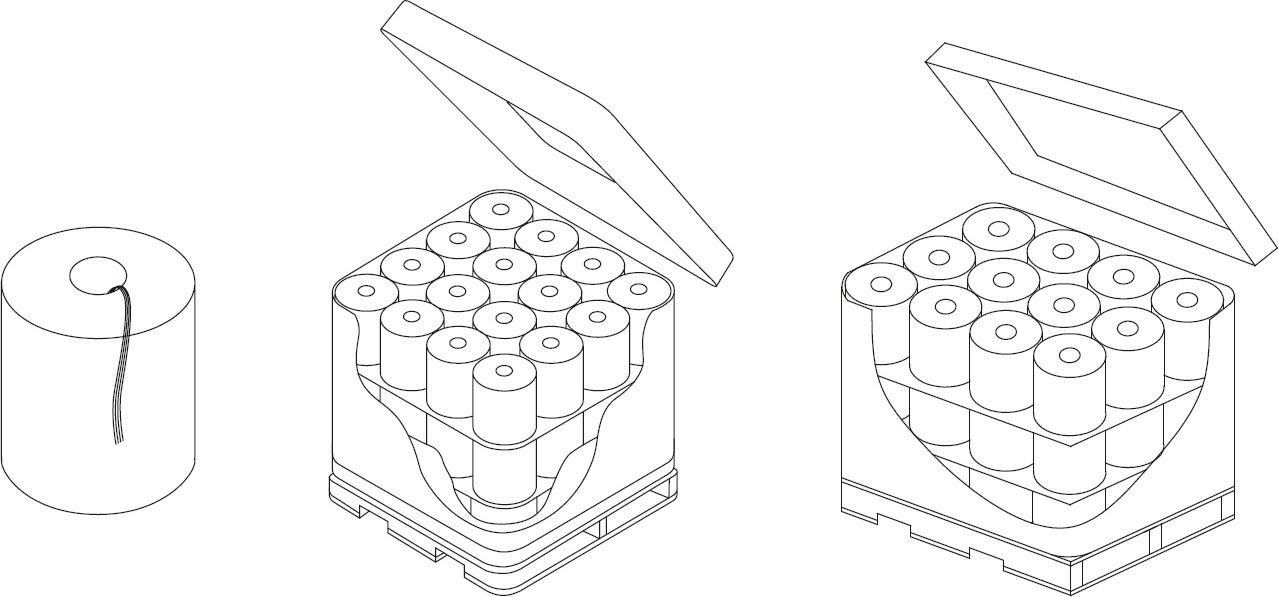

| Tus naj npawb ntawm cov txheej | 3 | 4 | 3 | 4 |

| Tus naj npawb ntawm cov doffs ib txheej | 16 | 12 | ||

| Tus naj npawb ntawm cov doffs ib pallet | 48 | 64 | 36 | 48 |

| Qhov hnyav tag nrho ib pallet kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Fiberglass direct rovingPallet ntev mm (in) | 1120 (44.1) | 1270 (50.0) | ||

| Fiberglass direct rovingPallet dav mm (hauv) | 1120 (44.1) | 960 (37.8) | ||

| Fiberglass direct rovingQhov siab ntawm pallet mm (hauv) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Tshwj tsis yog tias tau teev tseg lwm yam,cov khoom fiberglassyuav tsum khaws cia rau hauv qhov chaw qhuav, txias, thiab tsis muaj dej noo.

•Cov khoom siv fiberglassyuav tsum nyob hauvfiberglass direct rovingKhaws cia rau hauv lub thawv qub ua ntej siv. Qhov kub thiab txias hauv chav yuav tsum tswj kom nyob ntawm -10℃~35℃ thiab ≤80% feem.

• Yuav kom muaj kev nyab xeeb thiab tsis txhob ua puas rau cov khoom, cov pallets yuav tsum tsis txhob muab tso ua ke ntau tshaj peb txheej siab.

• Thaum cov pallets raug muab tso ua 2 lossis 3 txheej, yuav tsum tau ceev faj tshwj xeeb kom txav cov pallet sab saud kom raug thiab du.

Yog tias koj muaj lus nug txog peb cov khoom lossis daim ntawv teev nqi, thov tawm koj tus email rau peb thiab peb yuav tiv tauj koj tsis pub dhau 24 teev.